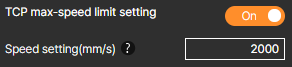

1. 2D Layout Image and 3D Equipments

① Layout Image Upload

You can upload and use 2D layout image. Using layout image facilitates the convenient placement of 3D equipment.

② Layout Equipment

You can use the 3D equipment library built into SafetyDesigner.

③ User Uploaded Equipment

Upload 3D CAD equipment files. You can upload STL, GLTF, GLB files under 20 MB, or STEP files under 100 MB.

2. Input Analysis Information (Collaborative Robots)

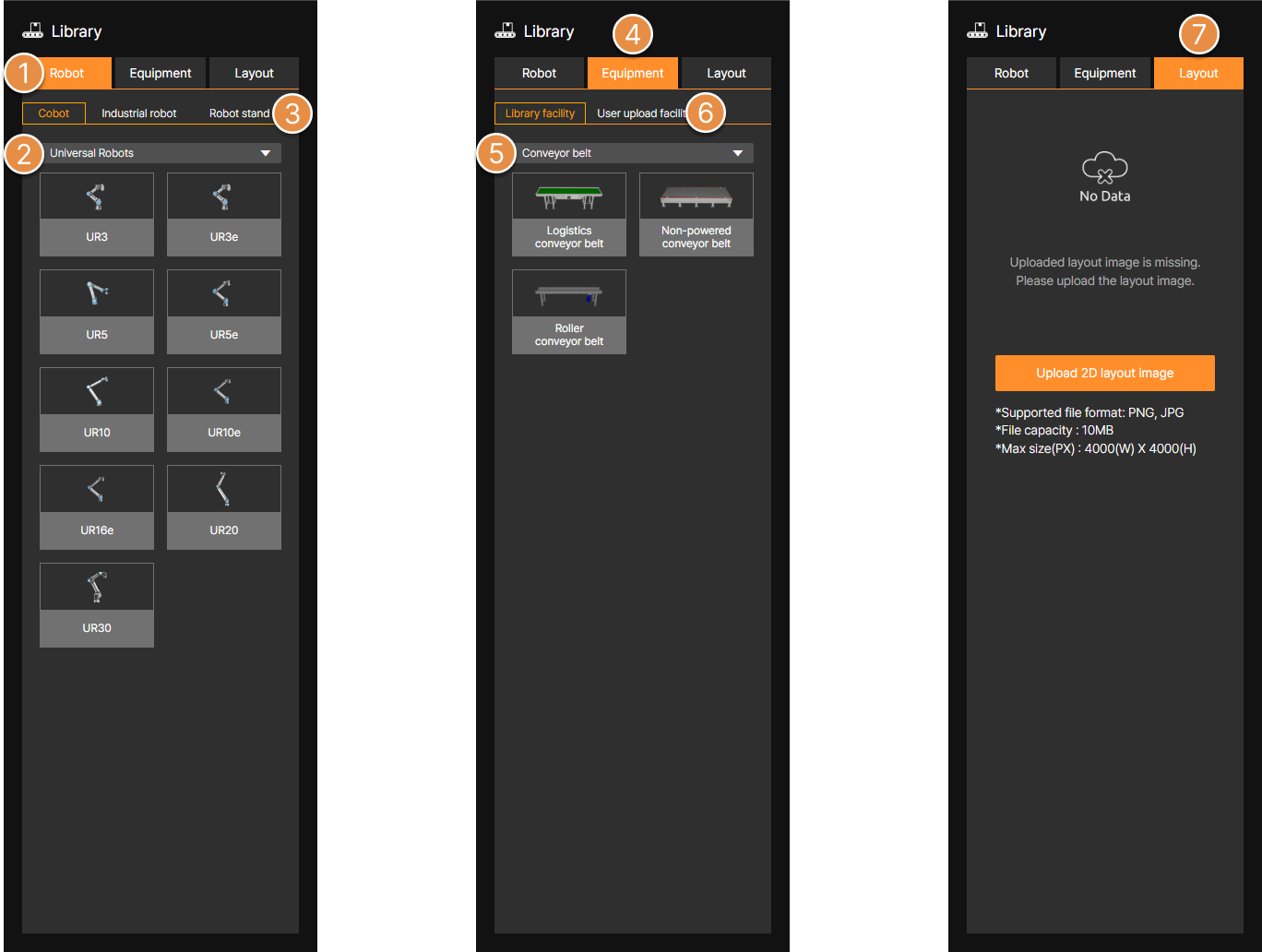

2-1. Gripper Settings

① Gripper position and direction setting

Set the position and direction of the gripper based on the robot’s last joint coordinate system position (6 axis).

② Gripper weight setting

Set the weight (Kg) of the gripper or workpiece and set the center of mass (COM).

🚨 The gripper’s weight cannot exceed the robot’s maximum payload.

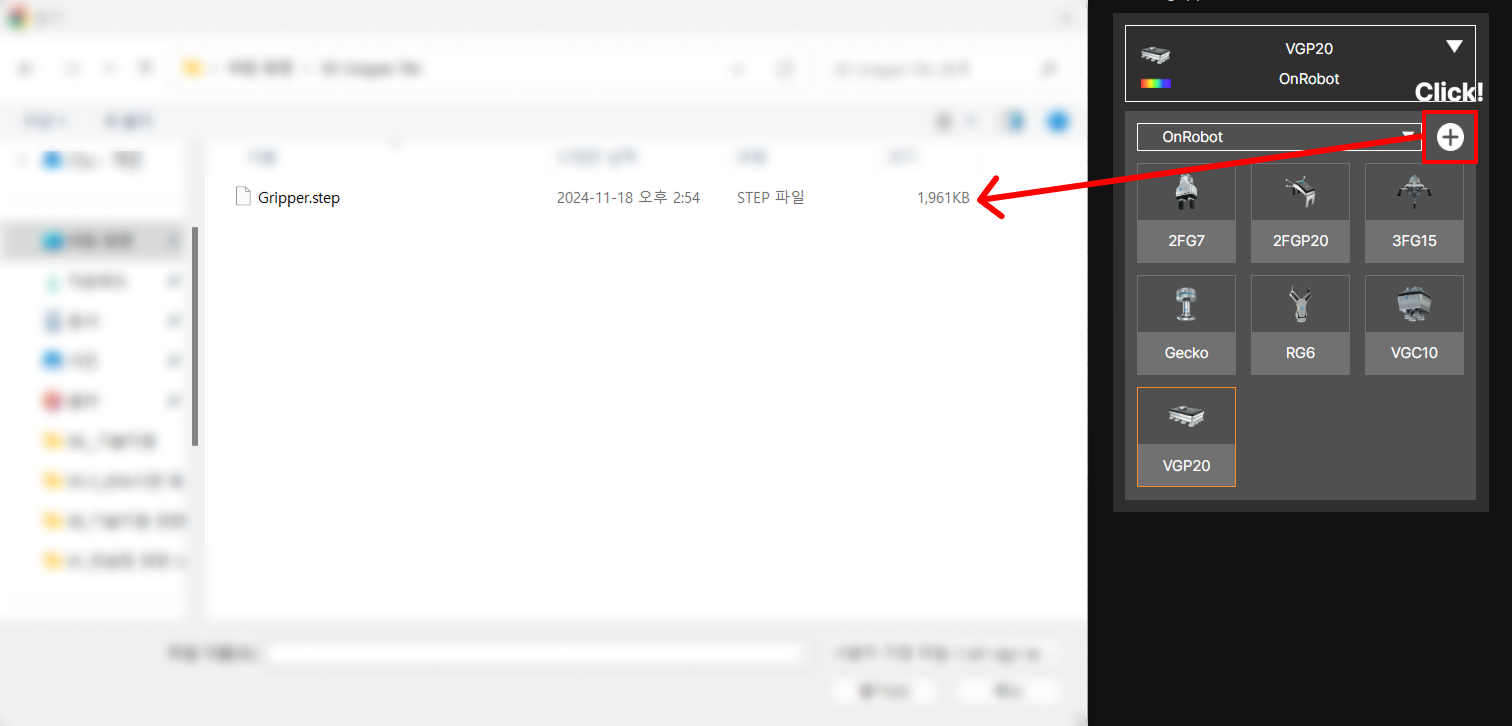

③ Select gripper

You can use either built-in grippers from the library or upload your own gripper file for collision risk analysis.

④ Upload custom gripper files

In addition to the default provided grippers, you can upload 3D gripper models to be used in the application. Gripper files can be uploaded with .STL, .GLTF, GLB files that are less than 20MB or STEP files less than 100MB.

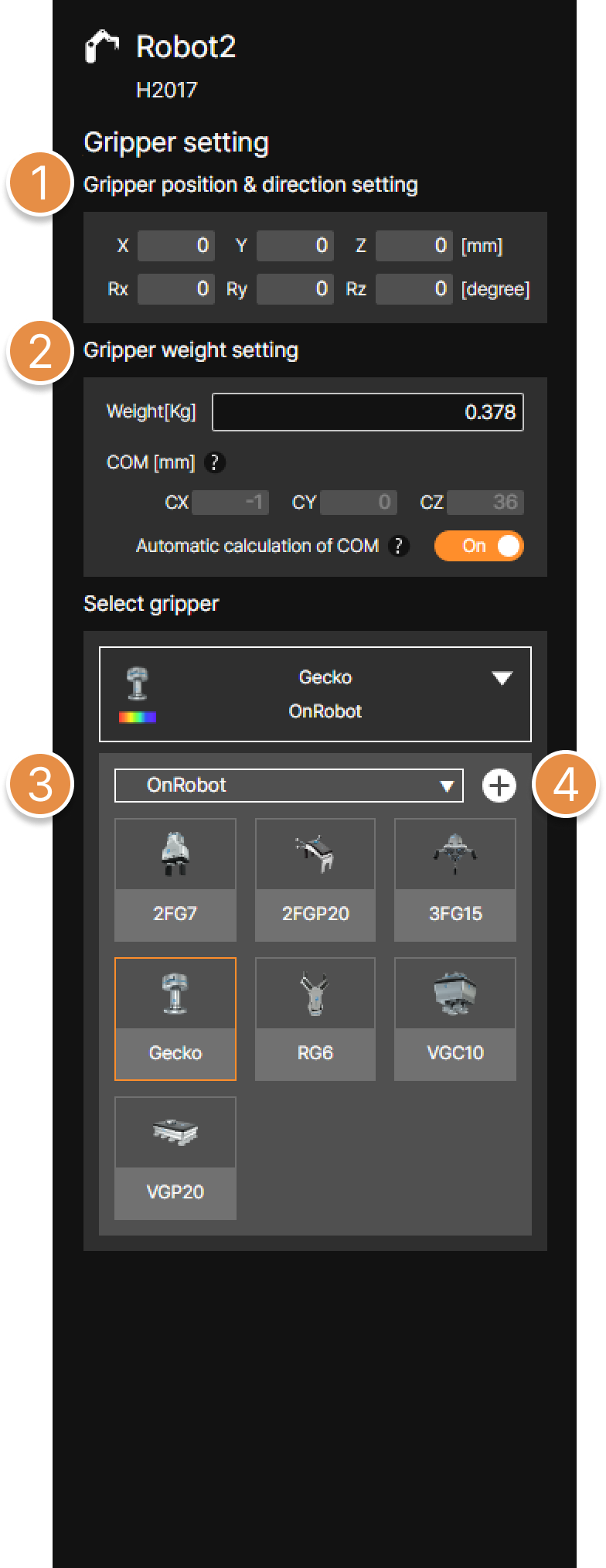

2-2. Create Collision Point

① Select shape of collision point

Select a shape to represent a collision point between the worker and the gripper or workpiece. After selecting the desired shape, click the desired location on the 3D screen with the mouse to create a collision point.

② Radius, Size(Height) and Fillet setting

You can set the radius of the created feature and the size of the fillet.

Cube – Size, Fillet

Cylinder – Radius, Height, Fillet

Half Sphere – Radius

Corner – Size, Fillet

③ Shape position and direction setting

Enter the location and direction of the collision point that you want to create.

🚨 The location of the collision point can be moved from -1000 mm to 1000 mm based on the origin of the gripper and the direction can be entered from -180° to 180°

④ Create on gripper

Restricts collision point creation to only within the bounds of the gripper 3D model.

Using the Display Vertex or Display Wireframe feature makes points and a wireframe appear on the edges of the gripper 3D model, allowing for easier creation of collision points

⑤ Collision points information

You can view or edit the information of the collision points that you have created.

2-3. Motion Settings

This section explains two methods for configuring robot motion.

2-3-1. Motion Settings 1 (Motion Upload)

① Motion upload tab

You can upload motion files extracted from an actual robot.

② Motion upload

Upload the motion file in the *.txt format extracted using the motion extractor program.

③ Waypoint List

You can view the waypoint information of the motion file that you have uploaded.

🚨 The waypoints of the uploaded motion are virtual waypoints calculated by SafetyDesigner’s algorithm, so they may differ from the actual configured values.

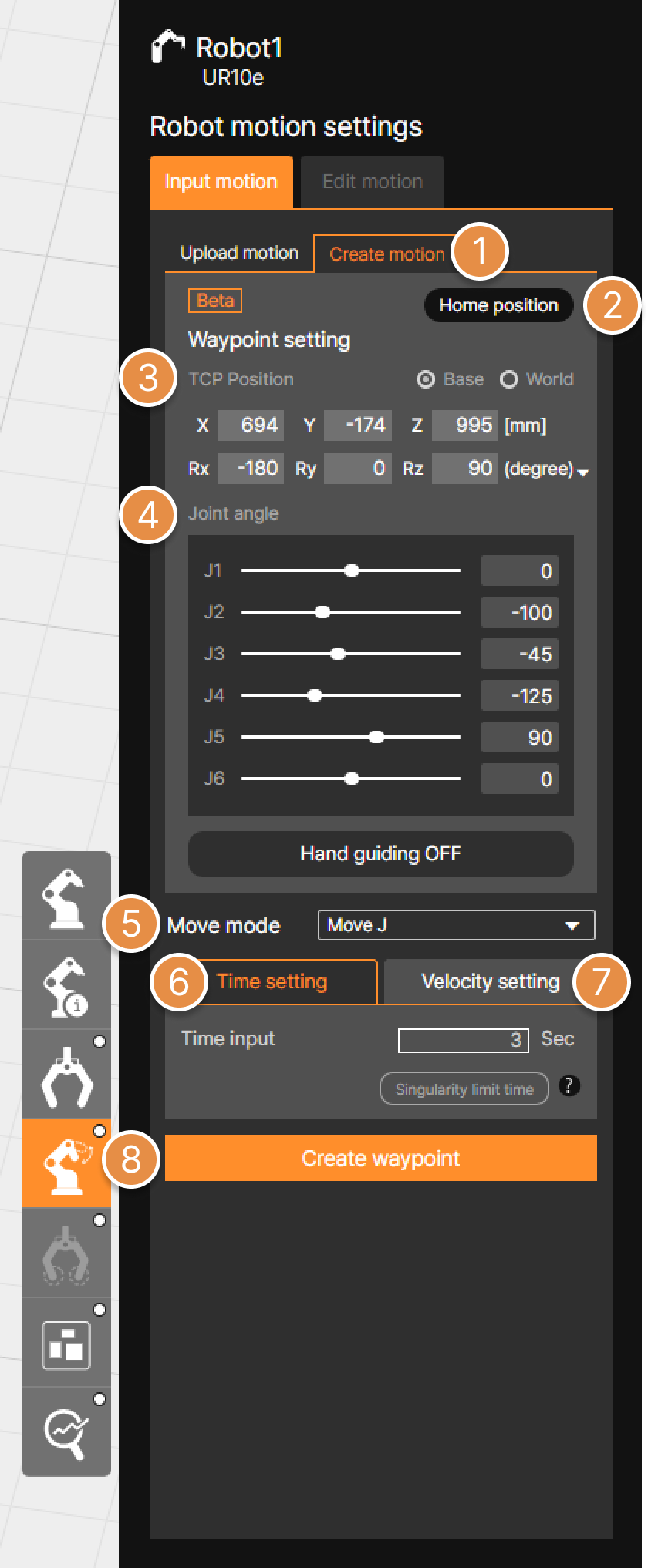

2-3-2. Motion Settings 2 (Create Motion)

① Hand guiding ON / OFF

When Hand Guiding is ON, you can create waypoints by teaching the robot on the 3D screen.

② Motion settings tab

Enter the Motion Creation (Waypoint Settings) menu.

③ Motion selection

Select either a move motion or a stop motion (Wait time), then configure the waypoint.

④ Waypoint Creation

Save the robot’s current position as a waypoint to create the motion. Created waypoints are displayed as blue dots on the 3D screen.

⑤ Waypoint List

A list of created waypoints and stop motions (Wait time) is displayed. Select a specific Waypoint from the list to modify its settings.

3. Input Analysis Information (Mobile Robots)

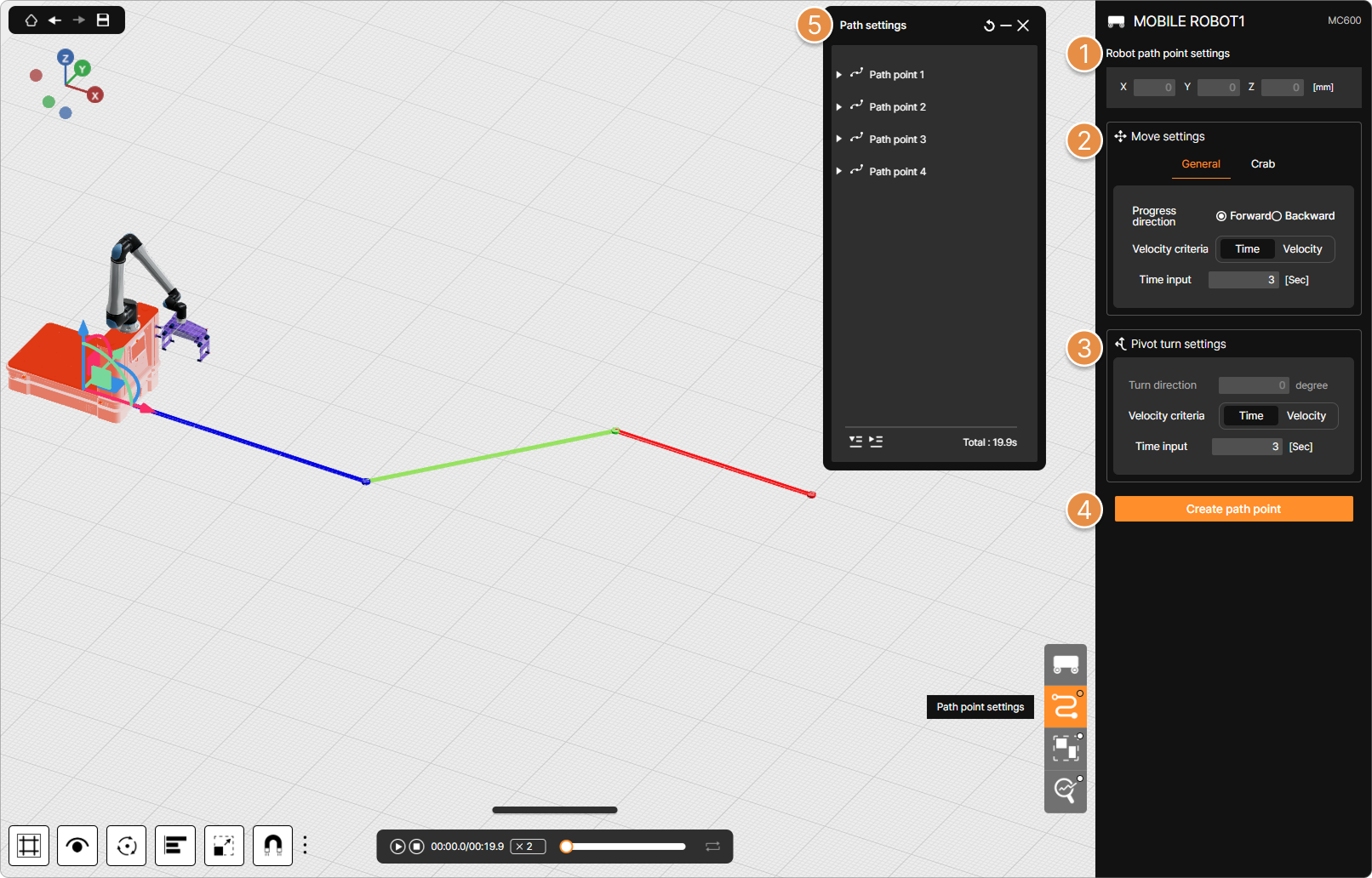

3-1. Path Point Settings

① Robot path point settings

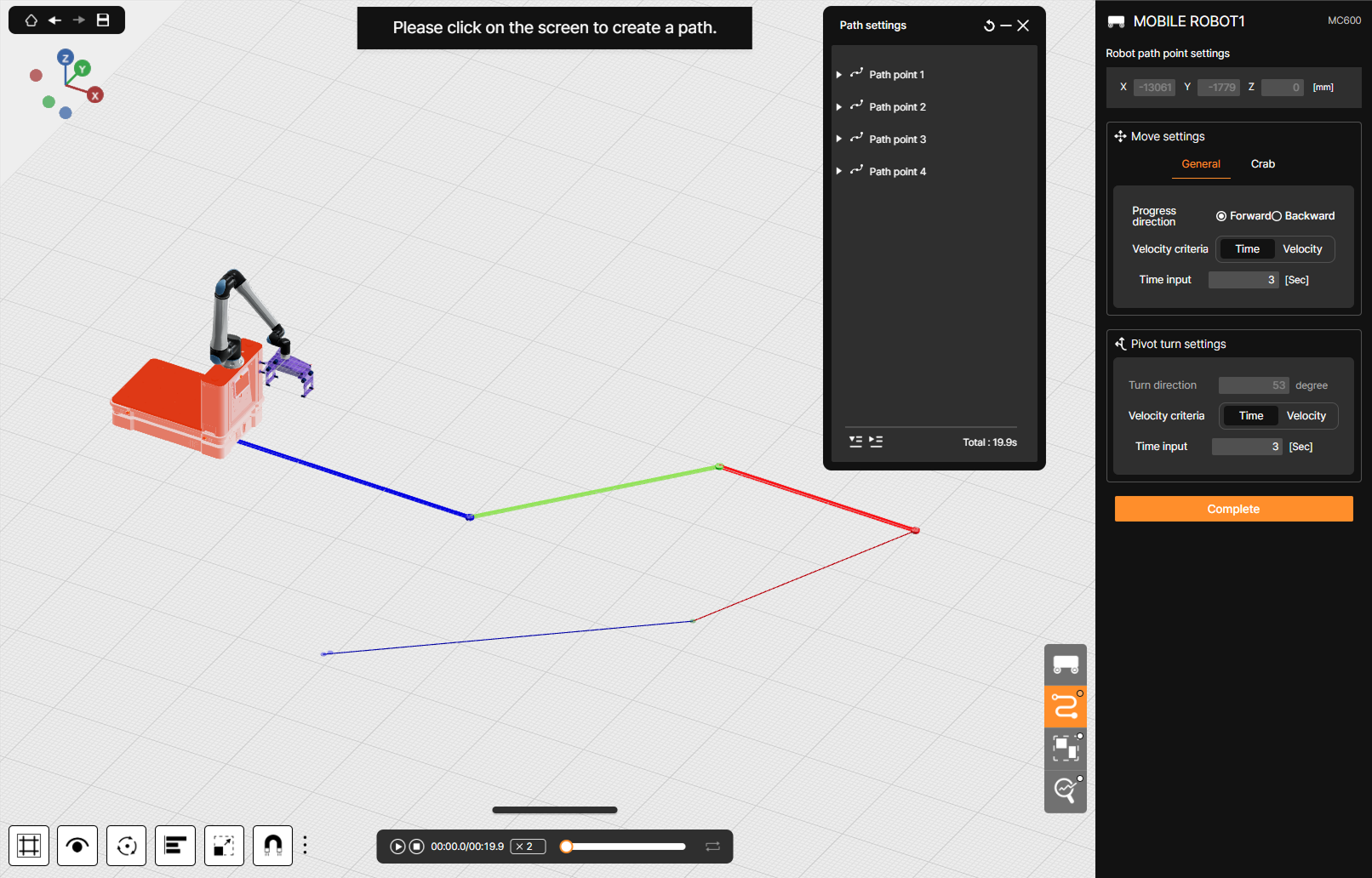

When path creation is initiated by clicking the Create path point button, the X and Y coordinates of the mouse cursor’s position are displayed, and a Path Point is created based on these coordinates. If an existing Path Point is clicked, its position can be modified by directly entering X and Y coordinate values in the relevant menu (referring to the Robot path point settings section, which includes X, Y, and Z).

② Move settings

When creating a Path Point, the mobile robot’s movement type (General / Crab), Progress direction (Forward / Backward), and Velocity criteria (Time / Velocity) can be configured.

③ Pivot turn settings

If the mobile robot needs to rotate before moving to the next point (e.g., when changing state from forward to backward), the turn direction, rotation speed or rotation time for that rotation can be configured.

④ Create path point

A robot’s travel path is constructed by creating Path Points based on the values configured above. With a creation mode enabled (after clicking Create path point button), a sequence of Path Points can be made by clicking desired locations on the 3D screen.

Forward path segments are displayed in blue, backward path segments in red, and Crab move path segments in green.

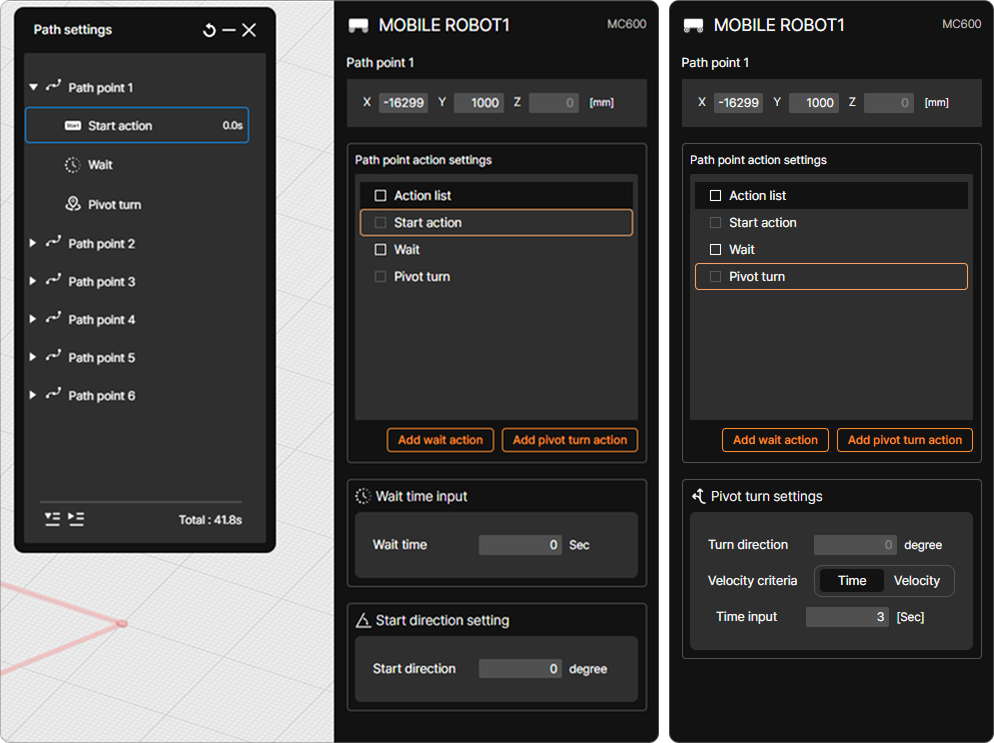

⑤ Path point List

A list of Path Points for the selected mobile robot is displayed.

Clicking the expand/collapse button (▼) to the left of each Path Point displays a menu on the right side of the screen where detailed settings for movement to that point and related actions can be modified.

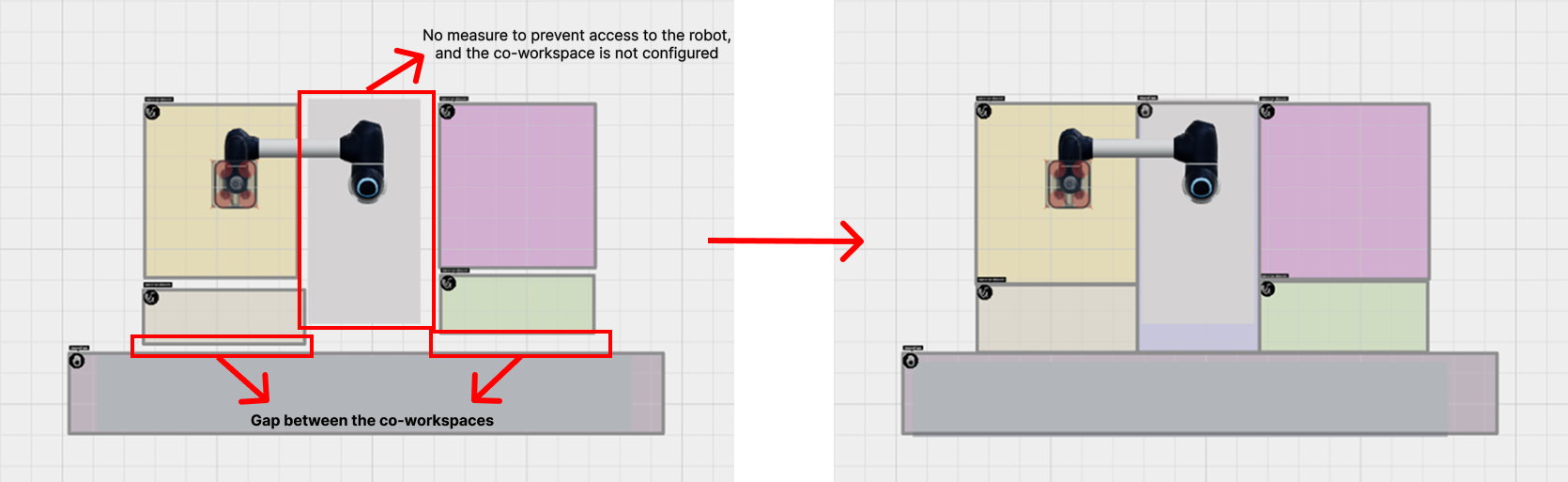

4. Collaborative Workspace Settings

Collaborative workspace refers to a workspace shared by robots and humans for collaborative applications.

When configuring the collaborative workspace, except in cases where protective measures (e.g. safety fences, electro-sensitive protective equipments) have been installed to ensure that the possibility of accessing the robot is zero, the collaborative workspace must be set up without any gaps across all operating spaces of the robot.

Furthermore, there must not be any collaborative workspace configured in empty areas outside the robot’s operating spaces that results in a CRI value of 0 in the analysis.

The following section explains how to use the collaborative workspace configuration menu.

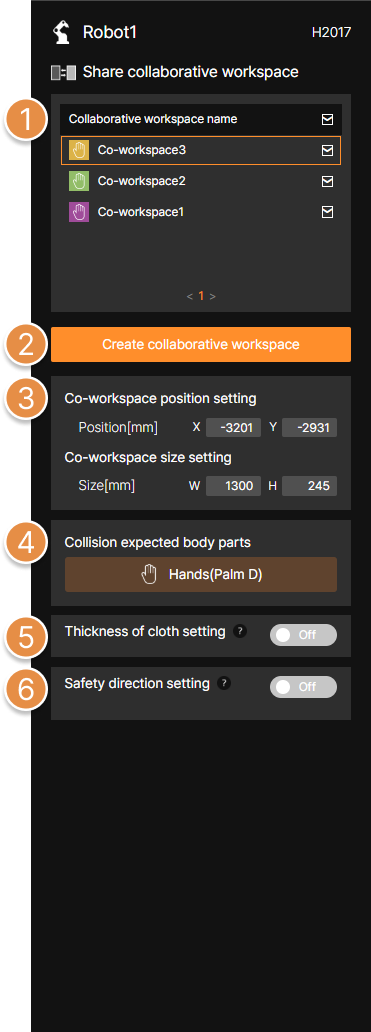

① Co-workspace position setting

Enter the position (mm) of the collaborative workspace.

② Co-workspace size setting

Enter the size (mm) of the collaborative workspace.

③ Collision expected body parts

Within the collaborative workspace, set the worker’s body part that is expected to collide with the robot.

When a collaborative workspace is created, the default body part is fixed as Hand (Palm); the body part can be changed when modifying the collaborative workspace.

🚨Standards (ISO/TS 15066, KOROS 1162-1) do not permit dynamic collisions involving the head.

– Hand (Palm)

– Chest (Sternum)

– Upper Arm (Deltoid muscle)

– Lower Arm (Forearm muscle)

– Thigh (Thigh muscle)

④ Thickness of cloth setting

Assuming the worker in the collaborative workspace is wearing clothing of the specified thickness.

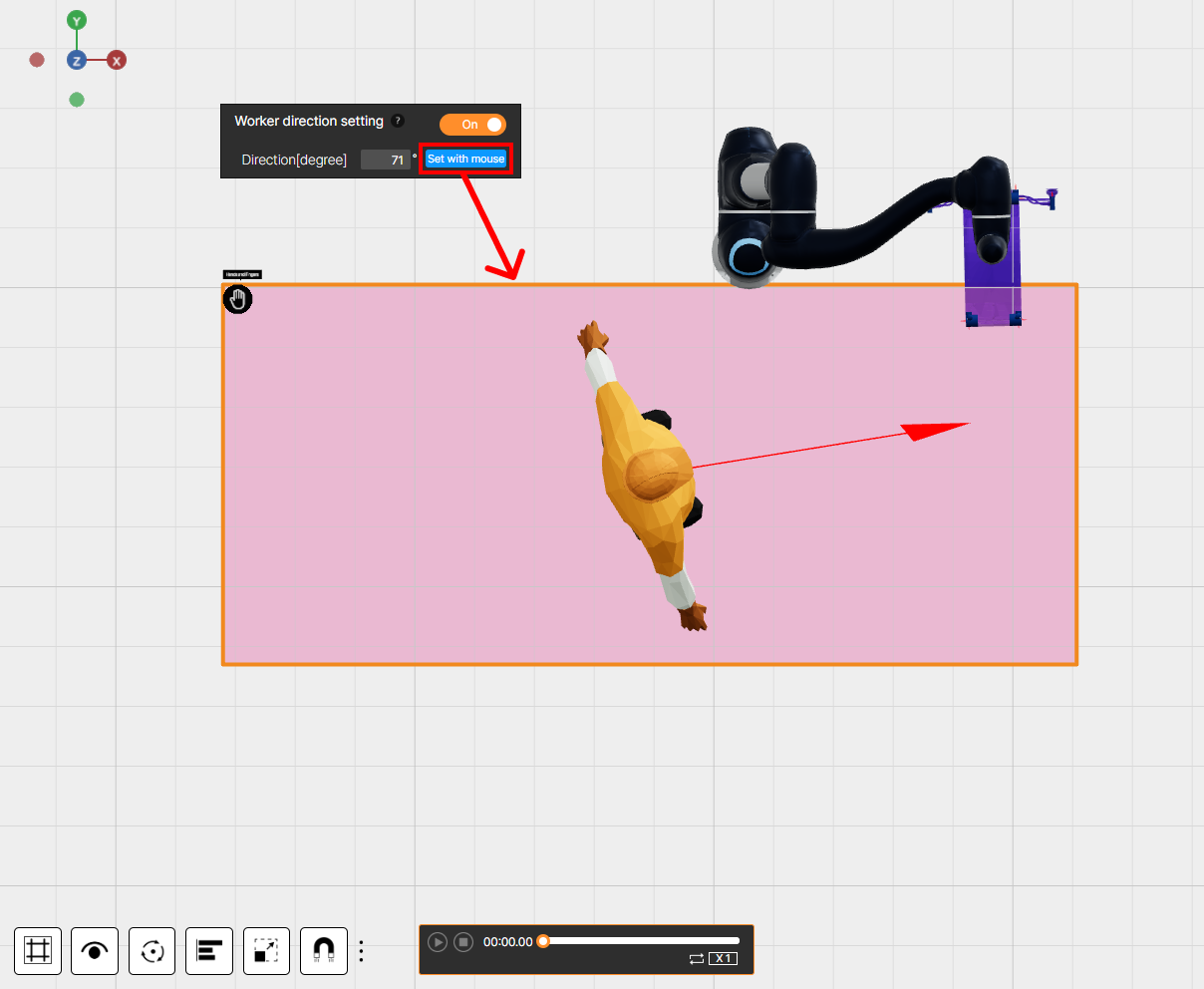

⑤ Worker direction setting

To calculate only actual potential collisions, set the direction the worker faces when operating within the collaborative workspace. Clicking the Set with mouse button with the mouse displays a worker model in the collaborative workspace; rotate the model to the desired orientation to specify the worker’s direction.

In collaborative workspaces where the this feature is applied, the ‘Chest’ and ‘Upper Arm’ body parts are merged and analyzed as a single region by an internal algorithm.

⑥ Create collaborative workspace

Configure the collaborative workspace on the 3D screen. The collaborative workspace is defined as a rectangular shape by dragging with the mouse on the floor area of the 3D screen.

⑦ Co-workspace List

Clicking the + or – buttons located to the left of the collaborative workspace name allows that workspace to be included in or excluded from the analysis for the currently selected robot.

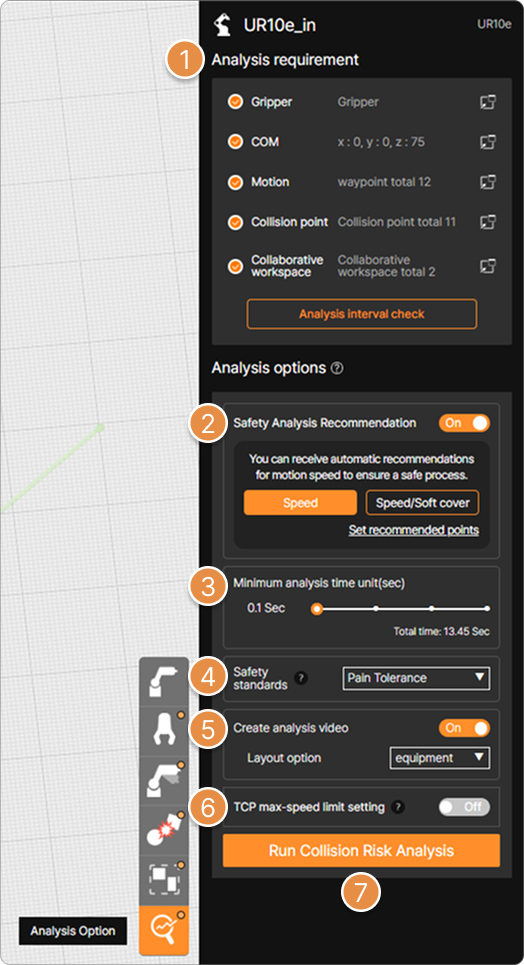

5. Analysis Option

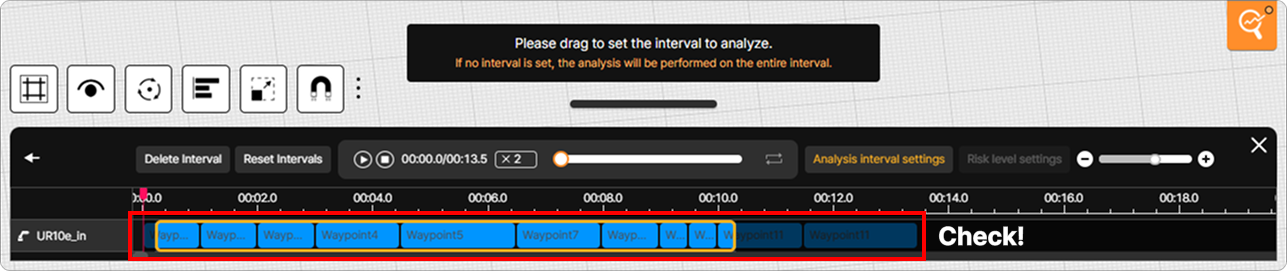

① Analysis requirement

Analysis information entered for the selected robot is listed. An orange check button is displayed to the left of items for which analysis information input is complete.

Clicking the Analysis interval check button displays a selection area at the bottom of the screen where the segment of the robot motion to be analyzed can be specified by dragging with the mouse.

② Safety Analysis Recommendation

Based on analysis results, recommendations are provided regarding acceleration/deceleration adjustments for each robot motion segment and the necessity of applying a Soft cover. The Safety Analysis Recommendation feature is not applicable to mobile robots or to collaborative robots that are combined with mobile robots.

③ Minimum analysis time unit(sec)

You can choose the unit of analysis time. The smaller the value, the more accurate the results and the longer the analysis time.

🚨 When generating the Collision Risk Analysis Report, the minimum analysis time unit must be set to 0.1 sec.

④ Safety standards

Choose a reference standard for collision risk analysis.

– Pain Onset (ISO TS 15066) : Run analysis based on the figure of pain starting point that people can feel. (International Standard)

– Pain Tolerance (KOROS 1162-1) : Run the analysis based on the highest level of pain a person can tolerate. (Korean Standard)

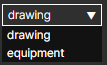

⑤ Create analysis video & Layout option

Choose whether to generate a video during the analysis. Selecting video generation will result in additional time required for the analysis.

🚨 Collision Risk Analysis Report cannot be issued unless the analysis video is generated.

Additionally, choose whether to display elements from the drawing or the equipment in the analysis video.

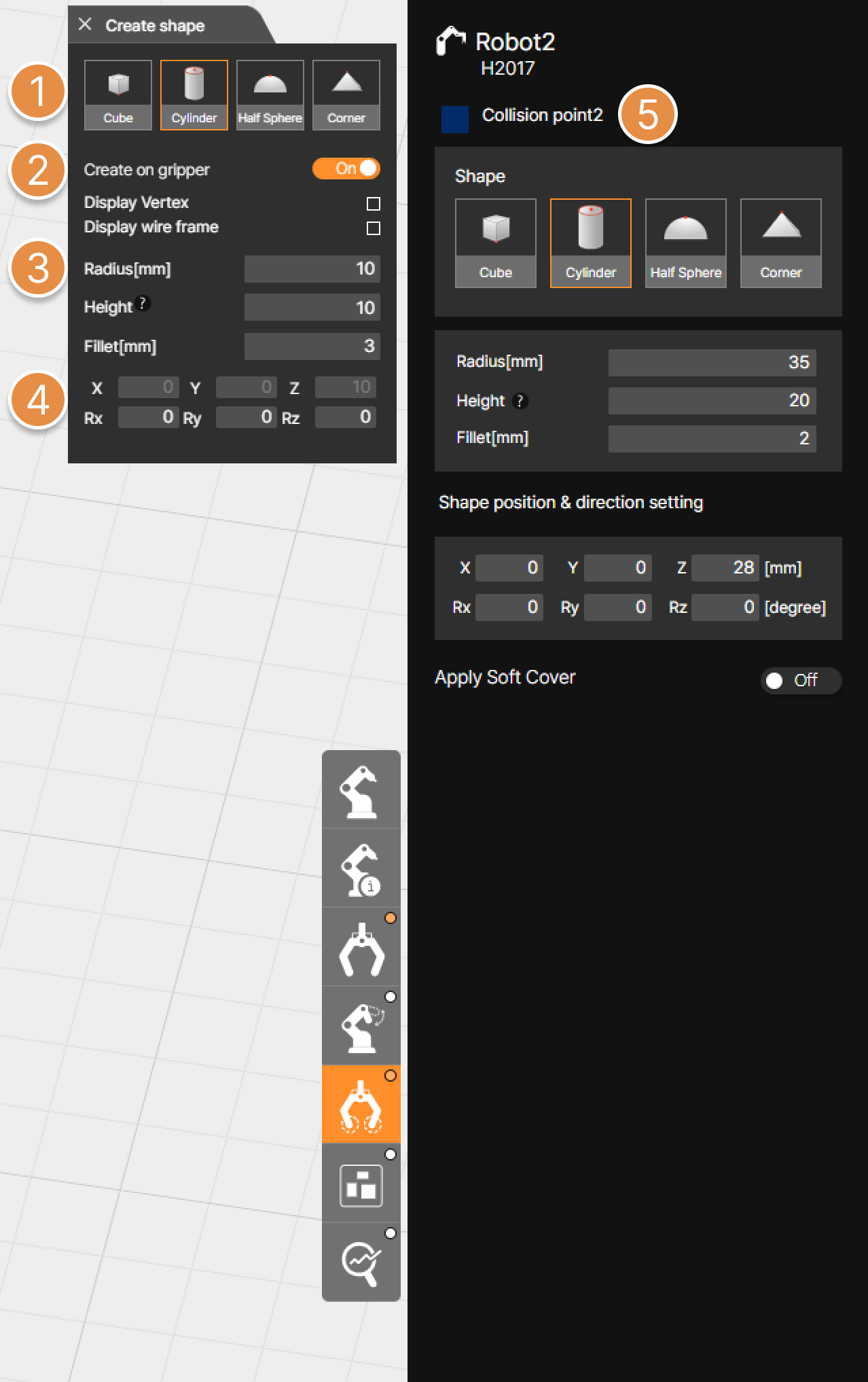

⑥ TCP max-speed limit setting

Limit the maximum speed of the robot’s motion. During motion, any intervals that exceed the value entered in the speed setting will be adjusted to the set speed and analyzed.

⑦ Run Collision Risk Analysis

Click to run the analysis. The time it takes to analyze depends on the length of the motion.