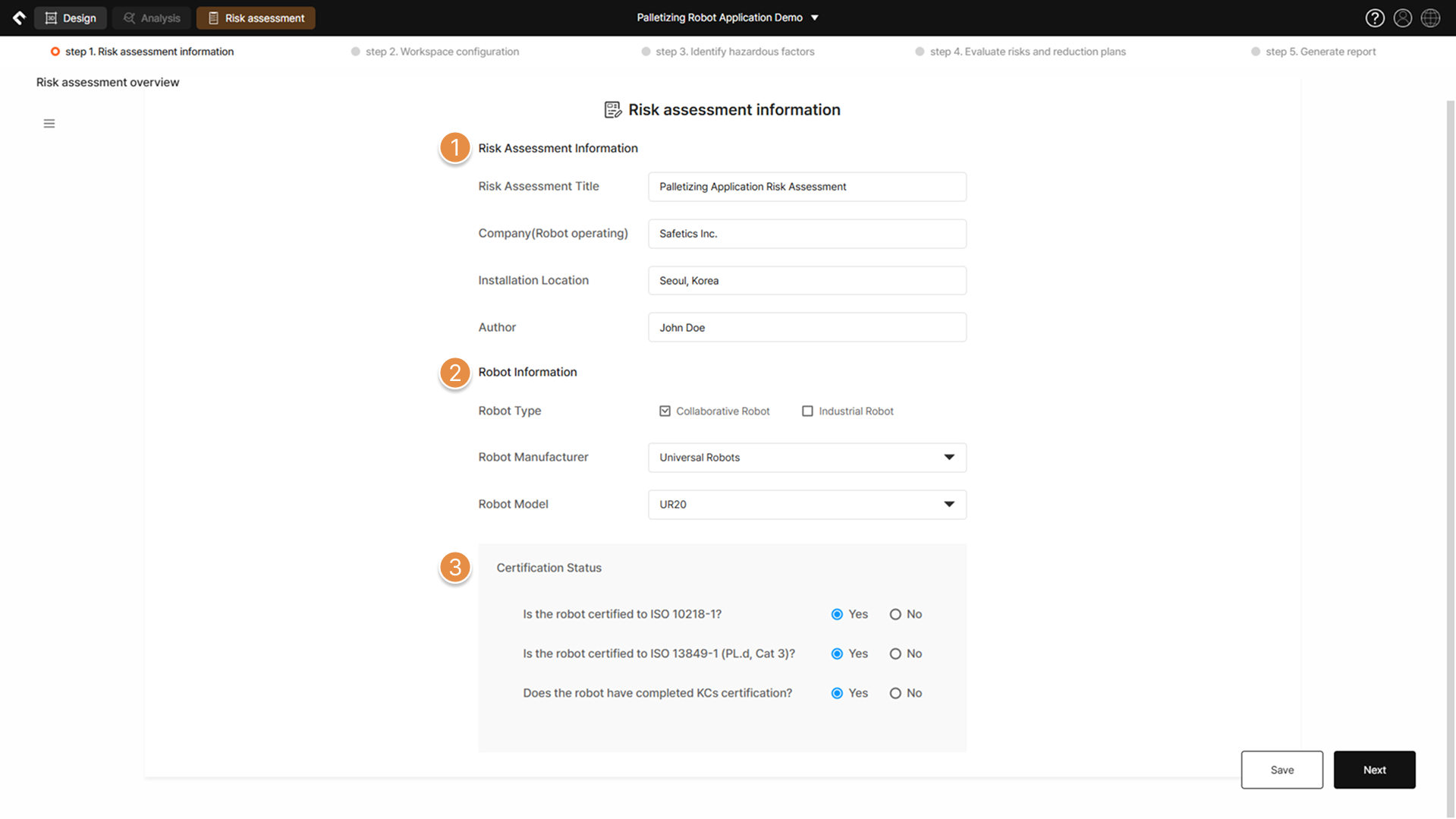

1. Robot System and Installation Information

① Risk Assessment Information

Enter the name of the robot system to be assessed, the robot user’s (company) name, the location where the robot is installed, and the name of the final author of the risk assessment (or the safety manager’s name).

② Robot Information

Select either a collaborative robot or a industrial robot. Additionally, enter the robot’s serial number, and either choose from the list or manually input the robot manufacturer and model name.

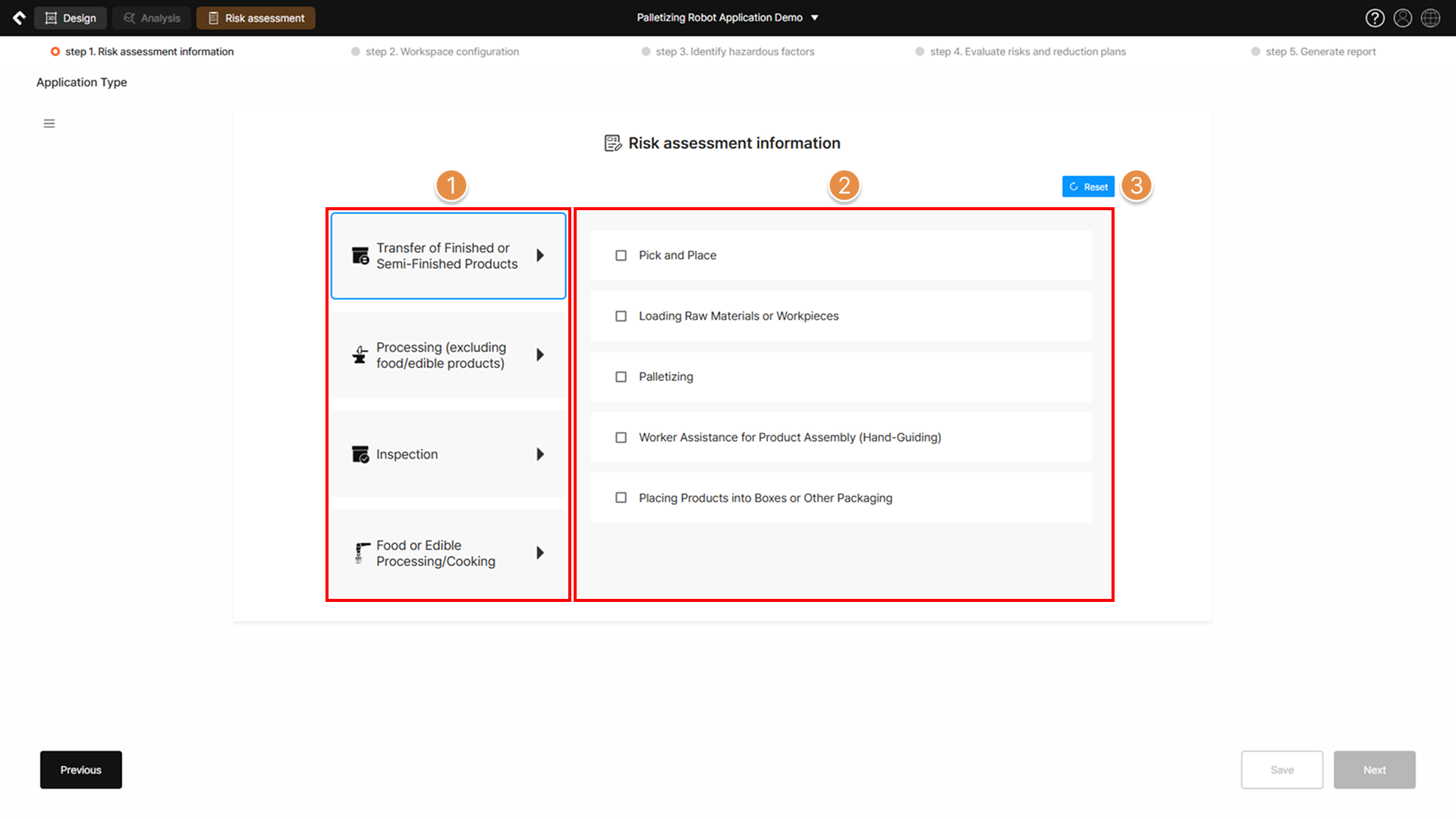

2. Robot Application Type

The selections made in this section will affect the questions in Step 3. Identify hazardous factors and Step 4. Evaluate risks and reduction plans. Therefore, be sure to accurately select the type of robot application for the risk assessment target.

① Main Category Selection

Select the main category for the robot application. Each main category includes various detailed application types.

② Detailed Item Selection

(Multiple selections possible) The sub-items under the selected main category are displayed.

③ Reset

Clears all selected sub-items.

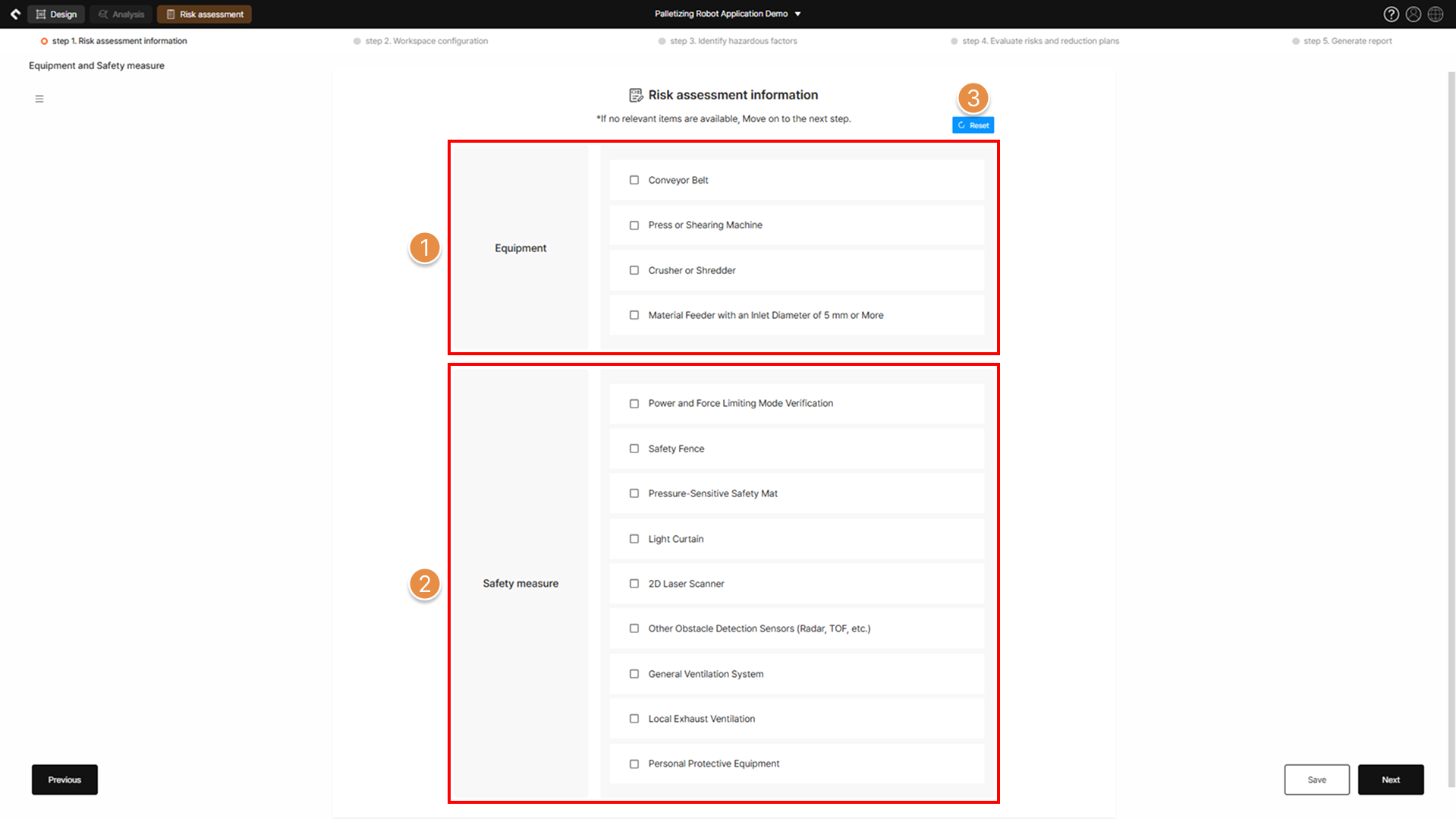

3. Equipment and Safety measure

The selections made in this section will affect the questions in Step 3. Identify hazardous factors and Step 4. Evaluate risks and reduction plans. Therefore, be sure to accurately select the equipment and safety measures for the risk assessment target.

① Equipment

(Multiple selections possible) Select all surrounding equipment that is either installed or planned to be installed within the robot system.

② Safety Measures

(Multiple selections possible) Select all safety measures applied to the robot system.

③ Reset

Clear all selected items.

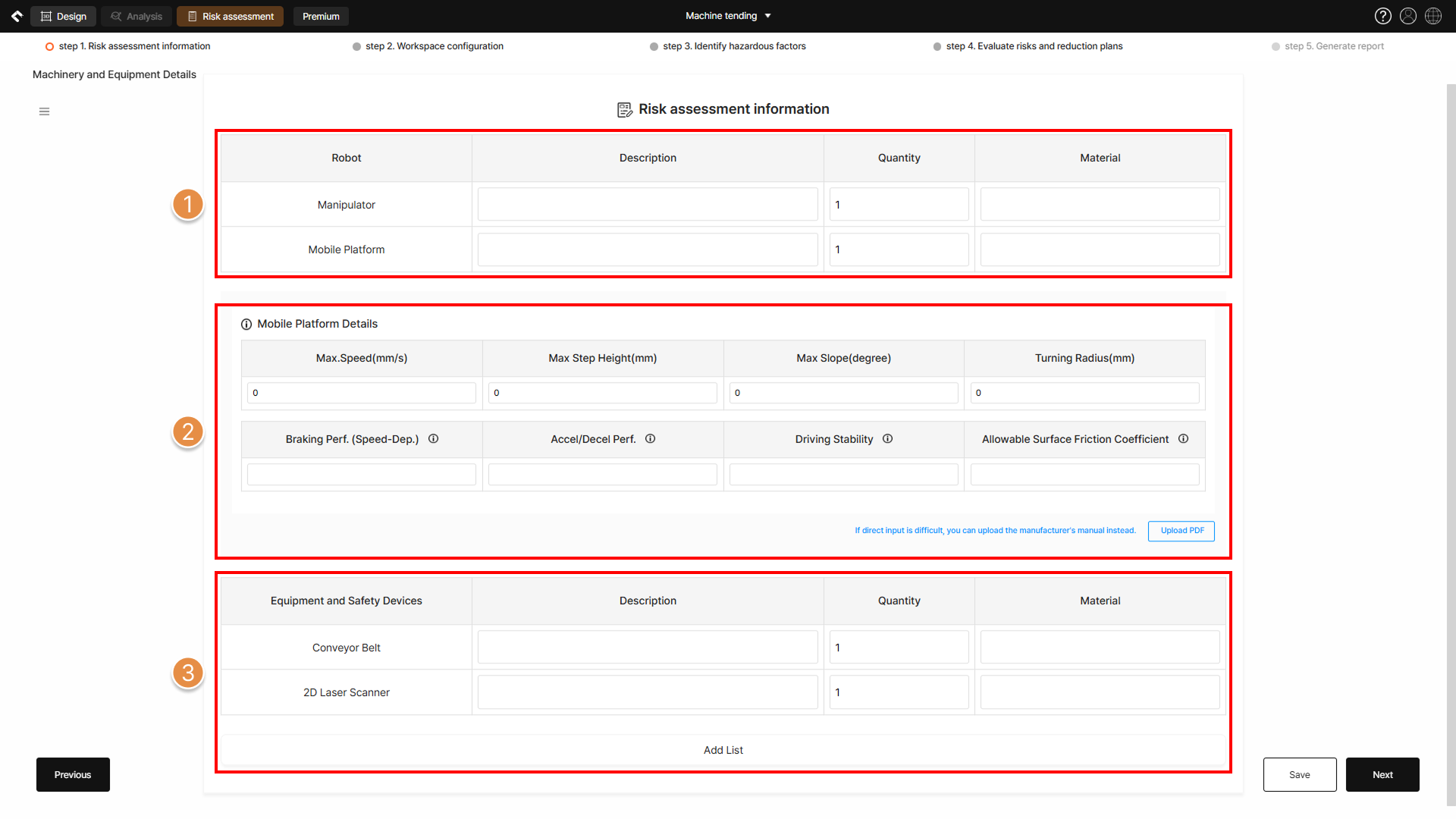

4. Machinary and Equipment Details

① Robot Information

Detailed information for robots installed in the process can be entered. The robot type, main purpose of use, etc., can be entered in the Description field, and primary materials such as metal or plastic can be entered in the Material field.

② Mobile Platform Details

(Activated only if a mobile robot exists in the robot application) Enter the mobile robot’s performance information. If performance information is not well known, the manufacturer’s manual can be uploaded instead.

③ Equipment and Safety Devices

A list of equipment selected from the equipment and safety device information is displayed. Model names of the equipment or safety devices can be entered in the Description field, and primary materials such as metal or plastic can be entered in the Material field.

If necessary, additional fields can be added by clicking the Add List button.

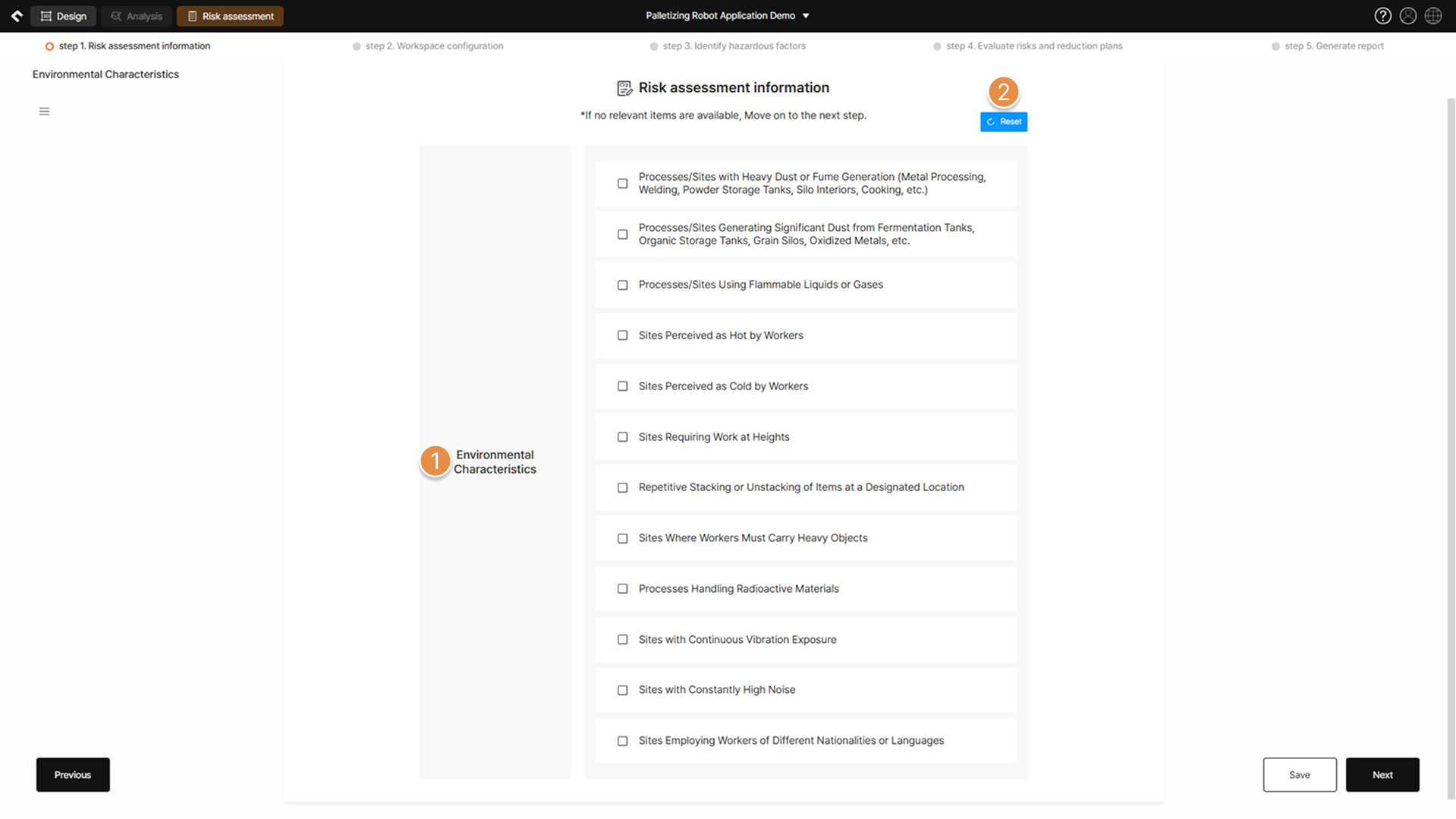

5. Environmental Characteristics

The selections made in this section will affect the questions in Step 3. Identify hazardous factors and Step 4. Evaluate risks and reduction plans. Therefore, be sure to accurately select the environmental characteristics for the risk assessment target.

① Environmental Characteristics

(Multiple selections possible) Select all environmental factors in the workspace where the robot system is applied.

② Reset

Clear all selected items.

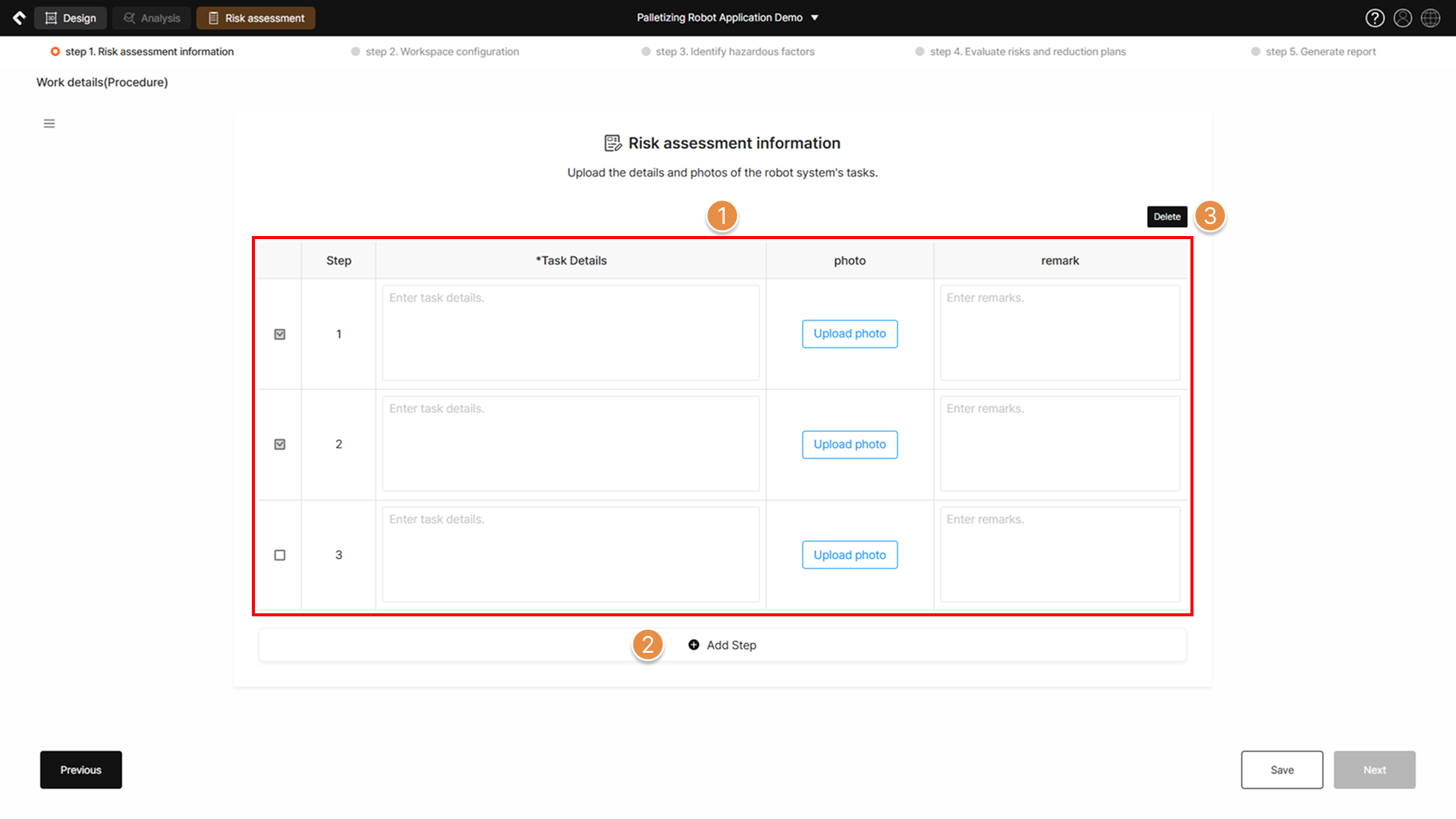

6. Work Procedure Information

Work Procedure is documented as a key element in the risk assessment report to clearly specify the tasks for which the robot system is designed and to define its control scope. Each work sequence should be recorded in as much detail as possible, and it is recommended to attach photos or images related to the task details.

① Input Work Procedure Information

Enter the taskk details according to the robot system’s work procedure, and attach a corresponding photo on the right for each work step.

Any additional information that the operator needs to reference, beyond the task details, should be entered in the remark section.

② Add Step

Three input fields are provided by default. If necessary, additional fields can be added by clicking the button.

③ Delete

When the checkbox to the left of a work step is selected and the button is clicked, the corresponding work details will be deleted.